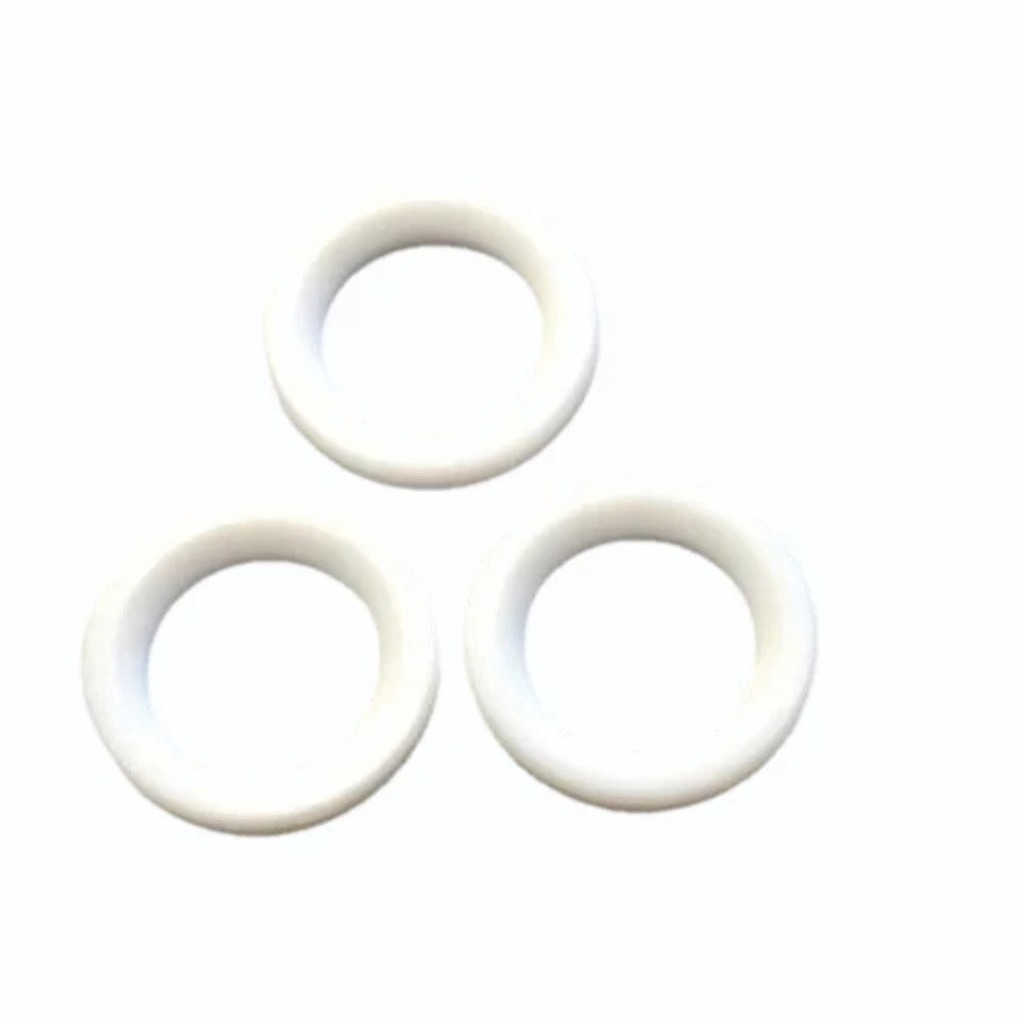

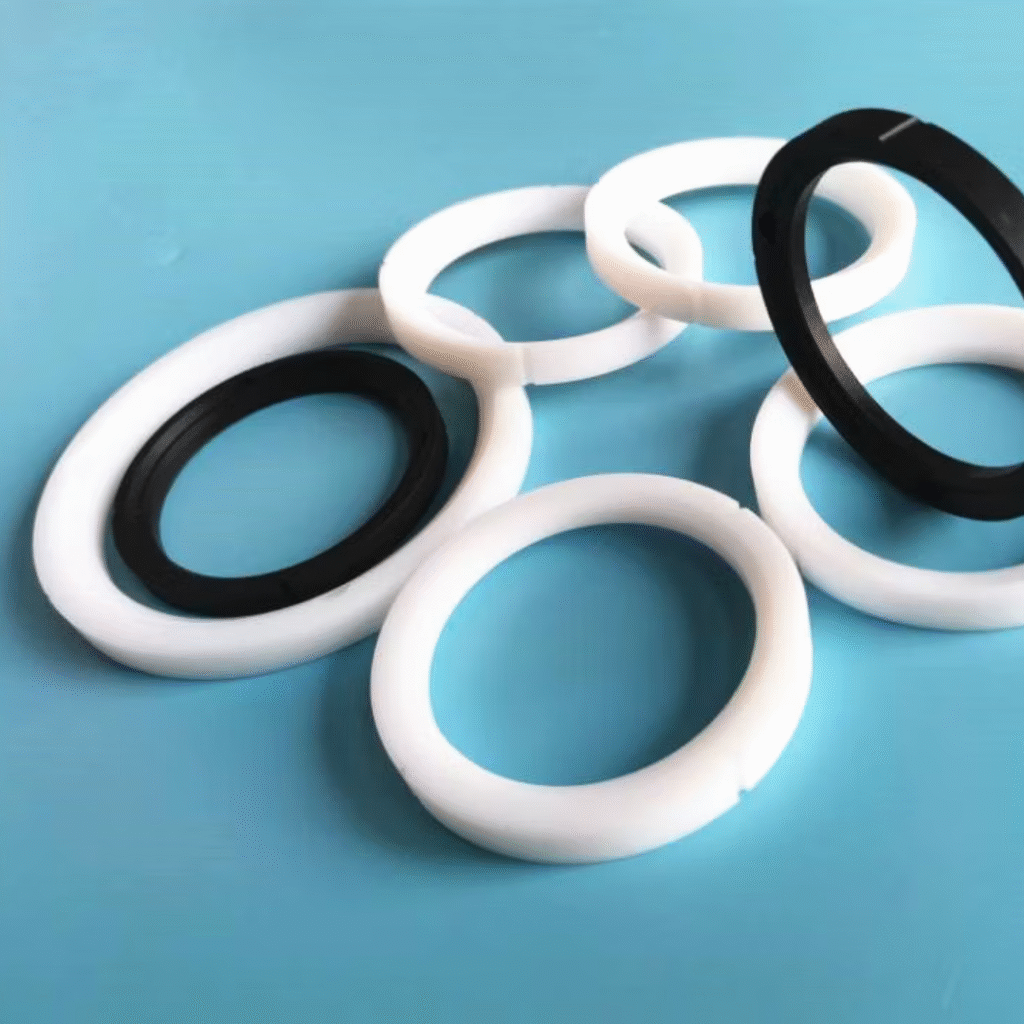

PTFE Valve Seat

The PTFE valve seat is an important part of the valve, which gives a good seal and smooth operation. This material is PTFE, a Polytetrafluoroethylene (PTFE) known for its excellent heat, chemical, and wear resistance. PTFE valve seats are also used in chemical, oil and gas, pharmaceutical, and food processing industries.

Major Features of PTFE

Durability and Long Lifespan

High-Temperature Resistance

Non-Stick Properties

Electrical Insulation

The PTFE valve seats are circular pieces mounted inside the valves to result in a leak-free seal among the moving parts. Teflon is generally a brand name for PTFE. This is white, waxy material with very non-stick properties, high temperature tolerance, and chemical resistance.

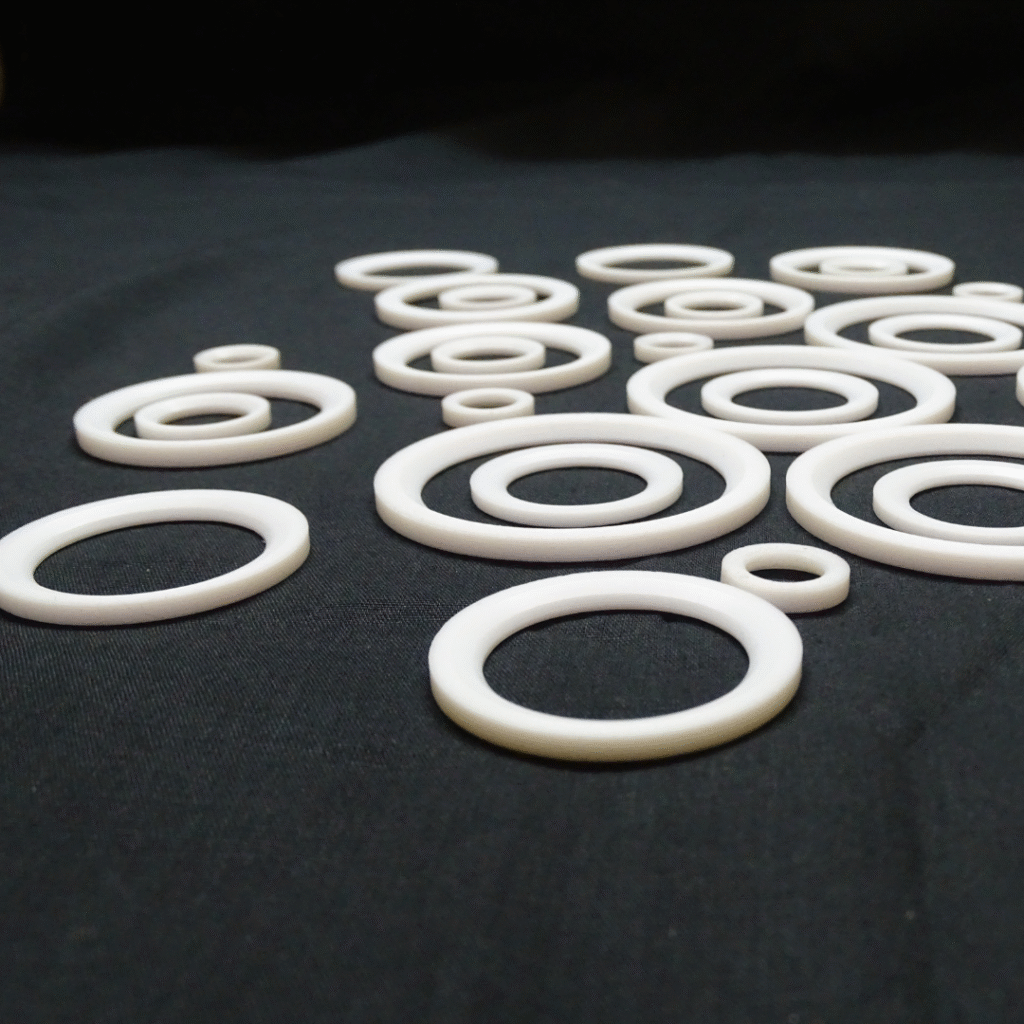

PTFE valve seats have been manufactured by Hindustan Polymer in different sizes of different shapes to conform to customers’ requirements. Both in low and high pressure applications, their PTFE valve seats are suitable and can work in harsh environments.

Hindustan Polymer is well known in the industry by its name for its credibility in the manufacturing of high-quality products as per the application.

Hindustan Polymers PTFE washers and valve seats have various benefits:

- Chemical Resistance: PTFE is almost chemically resistant to every type of chemical, acid, and solvent.

- Extreme Temperature Tolerance: Able to withstand very high and very low temperatures without melting or deforming.

- Low Friction: A Smooth surface reduces wear and ensures long-lasting performance.

- Non-Stick Surface: It doesn’t react to or stick to anything, making it great hygiene-sensitive industry.

- Durable and Long-Lasting: PTFE seats have a longer service life compared to traditional steel seats, which require frequent replacements.

- Excellent Sealing: Ensures leak-free performance in both static and dynamic sealing conditions.

Property | Value | Standards |

Material | Virgin PTFE, Glass-Filled PTFE, Carbon-Filled PTFE, etc | Custom blends available for specific applications |

Temperature Range | -40°C to +260°C (PTFE, filled PTFE, TFM) | Up to 320°C for Carbon Graphite filled TFM; PCTFE: -270°C to +260°C |

Pressure Range | Up to 100 bar (varies by seat design and material) | Higher pressure with reinforced/filled grades |

Chemical Resistance | Excellent, inert to most chemicals | Not suitable for molten alkali metals, fluorine at high temperatures |

Coefficient of Friction | Very low | Enables smooth operation and tight shut-off |

Hardness | Shore D 55–65 (Virgin PTFE) | Higher for filled grades |

FDA Approved | Yes (Virgin PTFE) | Suitable for food and pharma applications |

Types Available | Ball valve seats, butterfly valve seats, custom seats | Custom profiles and dimensions are available |

Wear Resistance | Good (Virgin PTFE), Improved (Glass/Carbon Filled) | Glass/carbon fillers enhance cycle life and durability |

Thermal Conductivity | 0.25 – 0.69 W/mK | |

pH Range | 0 – 14 | |

Applications | Chemical, oil & gas, food processing, pharma, water treatment, high-purity systems | Used in ball, butterfly, plug, and other valves |

Standards Compliance | API, DIN, EN, ASME | |

Special Features | Non-stick, low cold flow (RPTFE), fire resistant (RPTFE/TFM), high cycle life | Custom-engineered for demanding environments |

Applications of PTFE Valve Seats

Due to their robust properties, PTFE valve seats are used in a wide range of industries.

- Chemical Industry: For valves handling corrosive liquids and gases.

- Pharmaceutical: Hygienic systems to avoid contamination.

- Oil and Gas: Withstanding high-pressure and high-temperature environments.

- Food Processing: Nontoxic and nonreactive materials to ensure food safety.

- Water Treatment Plants: Corrosion-resistant for long-lasting use in damp conditions.

- Semiconductor Industry: Clean and chemically inert for ultra-pure applications.

Installation & Maintenance Guidelines: Best Practices for Installation

Proper installation is important for optimum valve seat performance. Here are a few tips:

- Clean Area: Remove any debris, dust, or old sealing materials.

- Check Alignment: Ensure that the seat is aligned with the valve body for no leaks.

- Use Proper Tools: Do not use a sharp tool that may damage the PTFE surface.

- Do Not Over-Tighten: Fitting with excess pressure will deform the seat.

- Regular Inspection: Periodically check for wear and replace if needed.

- Manufacturer Guidelines: Hindustan Polymer gives the particular guidelines for each product.

Top Manufacturer & Supplier of PTFE Teflon Sheets

If you choose a reliable supplier, you can guarantee your receipt of PTFE products that last longer and work better. Hindustan Polymer is a leading manufacturer and supplier of PTFE sheets and valve seats in India.

Every piece is made with the latest machines and top-quality materials for this reason. We are a trusted name in the industry as we are capable of making custom parts and delivering quickly.

Why Choose Hindustan Polymer?

For the most part, Hindustan Polymer is a well-known name in the PTFE products segment, for a reason. Every valve seat or sheet is their quality control, and we take it very seriously that everything works as it should.

- High-Quality Raw Materials: Our products are manufactured from reputable fillers and top-grade PTFE. This is so that our valve seats will be durable, long-lasting, and highly reliable.

- Advanced Manufacturing Facilities: We have modern machines and are run by well-experienced experts in all our production units. It allows us to keep precision, consistency, and fast delivery times.

- Customisation Options: Custom moulded PTFE valve seat to exact your requirements. Whether big, small, new, traditional design, old, or any shape, we will build it for you.

- Competitive Pricing: We believe in offering the best quality at affordable rates. We have fair pricing so that you get great value without compromising on performance.

- On-Time Delivery: We are conscious about delivery by time and never go back on our promises. You will also receive your orders with our efficient logistics.

FAQ about PTFE Valve Seat

PTFE valve seats are widely used in industries such as chemical processing, pharmaceuticals, food and water treatment. Their chemical inertia and thermal stability make them suitable for handling aggressive media and maintaining hygiene standards.

PTFE provides excellent chemical and thermal properties, but it has limitations, including sensitivity to deformation under high mechanical stress and high pressure. Additionally, it may not be suitable for applications associated with fluorine or melted alkaline metals.

The virgin PTFE is pure and provides maximum chemical resistance and flexibility. Stuffed PTFE incorporates additives such as glass or carbon to increase mechanical strength, reduce wear and reduce deformation under load, which makes it suitable for high-demand applications.

Yes, PTFE valve seats can be mechanised and sewn to meet specific design requirements including size, including size and filler materials. Adaptation ensures optimal performance and compatibility with various valve types and operating conditions.

Regular inspection is necessary for signs of wear or deformation. Ensuring proper installation and exposure to incompatible chemicals or excessive pressures will expand the service life of PTFE valve seats. Cleaning with appropriate solvents helps maintain their sealing efficiency.

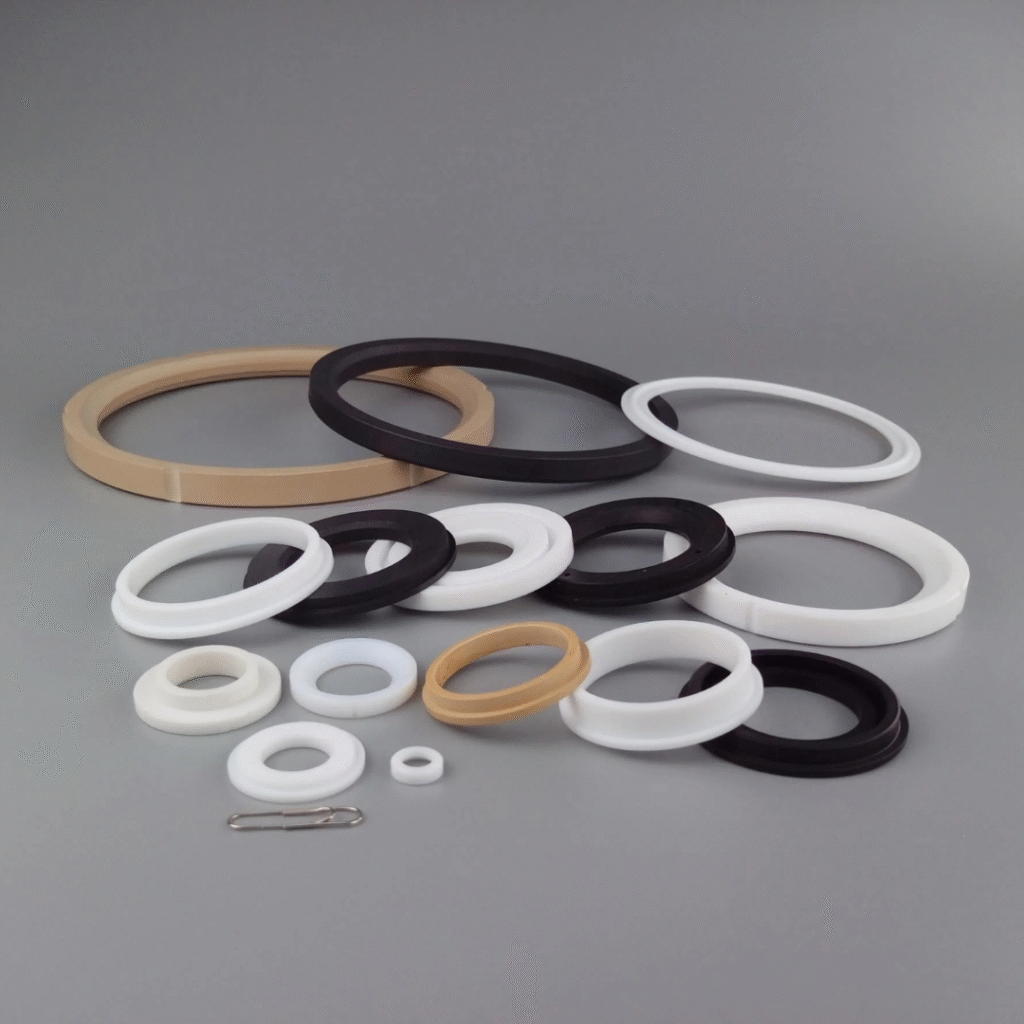

Related PTFE Valve Seats

Providing a broad variety of PTFE seat applications are offered by Hindustan Polymer. There are different types with unique features to answer different industrial requirements.

PTFE Ball Valve Seats

PTFE ball valve seats are designed to assist the valve ball rotate smoothly while sealing tightly and leak leak-proof. This is an excellent pickup for managing flow in chemical pipelines, water systems, and oil refineries, with long-lasting and efficient performance.

20 Inch PTFE Valve Seats

Our 20-inch PTFE valve seats are produced for large capacity industrial valves for high volume duties. They are commonly used in water treatment plants, power stations and infrastructure systems that are constantly demanding durability and strength.

Standard PTFE Valve Seats

Standard PTFE valve seats for common valve sizes are suitable for general use. They are low-cost, reliable, and can be applied to industries such as water management, chemical handling, and process automation.

PTFE Reinforced Valve Seats

Our PTFE valve seats are strengthened with fillers such as glass or carbon to provide additional strength and pressure resistance. This type of reel is best for heavy-duty operations that involve oilfields, mining, and other kinds of plants where durability is the primary concern.

PTFE Valve Seats with Elastomeric Inserts

Flexible, extended sealing can be achieved through the use of PTFE with rubber-like materials in our PTFE seats with elastomeric inserts. For units processing food, beverage and pharmaceutical products, pressure fluctuations are adequately handled by these.

PTFE Graphite-Impregnated Valve Seats

Our graphite impregnated valve seats combine graphite and PTFE to improve thermal resistance and reduce friction. Good for high temperature applications such as steam valves, heaters, heat exchangers, and thermal fluid systems.

PTFE/Carbon Composite Valve Seats

The PTFE/carbon composite valve seats we provide are built for strength and for how often they are used. For refining and petrochemical applications where valves operate continuously under low-wear, high-reliability environments, these are perfect.

Custom-Moulded PTFE Valve Seats

We manufacture custom moulded PTFE valve seats to your exact requirements. Our team can develop the perfect right fit for your equipment regardless of whether it’s from a unique size, shape or usage condition.

PTFE Lined Valve Seats

PTFE-lined valve seats manufactured by us use PTFE over a rigid or metal core. The chemical resistance of PTFE with the mechanical strength of metal is suitable for aggressive and high-load systems provided by this hybrid design.

PTFE Soft-Faced Valve Seats

The soft-faced PTFE valve seats are capable of providing better sealing even in low-pressure setups. They are soft surfaces, and due to the softness, they will adapt to any small imperfection and are ideal for use where a precise sealing without a perfectly machined part is required.

PTFE High-Performance Valve Seats

Our PTFE valve seats are made to withstand extreme conditions such as high heat, corrosive chemicals, heavy flow, etc. They are trusted by industries that have to operate within the toughest of working environments that require consistent operation.