Glass-Filled PTFE

Glass-filled PTFE is a type of PTFE (polytetrafluoroethylene) specially made by mixing glass fibres with PTFE. It strengthens and improves the wear resistance of the material. In some applications, PTFE is soft and will wear out quickly. With added glass fibres, it is stronger and lasts longer.

Major Features of PTFE

Durability and Long Lifespan

High-Temperature Resistance

Non-Stick Properties

Electrical Insulation

Glass-filled PTFE is made by adding glass fibres (the addition is of 5 to 25 per cent) to pure PTFE. Such a mix, based on PTFE, retains, like the original, good chemical resistance and low friction, but improves the mechanical strength. It is available in sheets, rods, gaskets, washers, and valve parts that are commonly available.

At Hindustan Polymer, we provide high-quality glass-filled PTFE products to meet different industrial needs. They are meant to work in high temperatures, harsh chemicals, and are supposed to be in use continuously.

The most common applications for glass-filled PTFE are companies involved with chemical, automotive, electrical, and food processing. Get a wide range of glass-filled PTFE products from us.

Before choosing the glass-filled PTFE, it is important to understand its properties. It has some strong points and also a few limitations.

Strengths

- High strength: Glass fibres make PTFE stronger and harder.

- Improved wear resistance: Resists wearing to the last in various moving or rubbing applications.

- Chemical resistance: Resists acids, solvents, and bases.

- Low friction: A Smooth surface helps in easy movement

- Temperature tolerance: These can work in hot as well as cold environments.

- Dimensional stability: It retains its shape under pressure and temperature variations.

Weakness

- Lower flexibility: Glass fibres decrease the flexibility of PTFE.

- Higher cost: Slightly more expensive than pure PTFE.

- Brittleness: Gets brittle in very cold conditions.

- Not for electrical use: Glass reduces PTFE’s good electrical properties; therefore, it’s not for use in electrical applications.

Here are some common technical features of glass-filled PTFE. These may vary depending on the exact type and percentage of glass used:

Property | Typical Value |

Glass Fibre Content | 15% to 25% by weight |

Operating Temperature Range | -200°C to +260°C |

Hardness | 60–70 Shore D |

Tensile Strength | 20–30 MPa |

Density | 2.2–2.4 g/cm³ |

Coefficient of Friction | 0.1–0.2 |

Water Absorption | < 0.01% |

Typical Applications Across Industries

Glass-filled PTFE is not being used in one specific industry. The great bulk of its use is connected with its strong and long-lasting as well as chemically resistant state being employed in so many fields.

Here are some common applications:

- Chemical industry: Used in seals, gaskets and linings in contact with strong acids and chemicals.

- Automotive industry: Ideal for piston rings, seals, and valve components.

- Food processing: Where there are low to high temperatures, nonstick and easy-to-clean materials are needed.

- Pharmaceuticals: Preferred in clean and non-reactive environments.

- Electrical industry: Used in low-friction (not best for insulation) mechanical parts of the electrical industry.

- Oil and gas: Seals and gaskets for high-pressure and high-temperature areas.

- Aerospace: Lightweight, strong, and resistant to extreme conditions

Design Considerations & Material Variability

Before selecting a glass-filled PTFE, you should consider how it will be utilised. This makes it work well in your specific application.

- Glass percentage: More glass, more strength, but less flexibility.

- Operate temperature: Ensure that the part remains within a safe processing temperature.

- Surface finish: Glass has a rougher surface finish than true PTFE.

- Machinability: Can be easily cut or shaped; however, tools must be sharp to avoid cracking

- Shape and size: Available in many shapes, like rods, sheets, gaskets, etc.

Key Benefits of Choosing Hindustan Polymer's Glass-filled PTFE

As important as deciding on what material to use, choosing the right supplier for glass-filled PTFE is. Why do many customers trust Hindustan Polymer?

- High-quality materials: All of our products are built with fine glass fibres and top-grade PTFE. This is important to help give reliable performance in difficult industrial conditions.

- Custom solutions: We provide different shapes, sizes, and glass percentages based on your exact requirement. We can make it, whether you want a sheet, rod, or special part.

- Fast delivery: We know time is important in the industry, and we don’t want to waste time delivering products quickly. We have the ability to deliver on your project deadlines.

- Experienced team: We can help you pick the right material for your needs. They show you how to design, pick, and apply.

- Competitive prices: Quality products with the best value that we provide to you are at affordable rates. It gives terrific performance without blowing the budget.

- Customer support: Before and after purchase, our team provides friendly support. Never hesitate to contact us if you need help with something.

FAQS on Glass-filled PTFE

Glass-filled PTFE products offer increased strength, better wear resistance and low thermal expansion. It also performs better in high-temperature environments, making it ideal for industrial uses that require durability without compromising chemical resistance.

Yes, glass-filled PTFE can withstand higher temperatures than standard PTFE. It remains stable at temperatures up to 260°C (500°F), which is suitable for applications in industries such as chemical processing, motor vehicle and food processing.

Glass-filled PTFE provides better power and wear resistance than other fillers such as carbon or graphite. It excels in mechanical applications where high load-bearing capacity and dimensional stability are essential, while still maintaining excellent chemical resistance.

Yes, Glass-filled PTFE is usually used in sealing applications due to its excellent chemical resistance and low friction properties. It is particularly beneficial for creating gaskets and seals in pumps, valves and other machinery in contact with extreme conditions.

Glass-filled PTFE is harder and more abrasive than standard PTFE, which makes it more challenging for the machine. However, it can still be processed using traditional machining techniques, although carbide equipment may be necessary for optimal results.

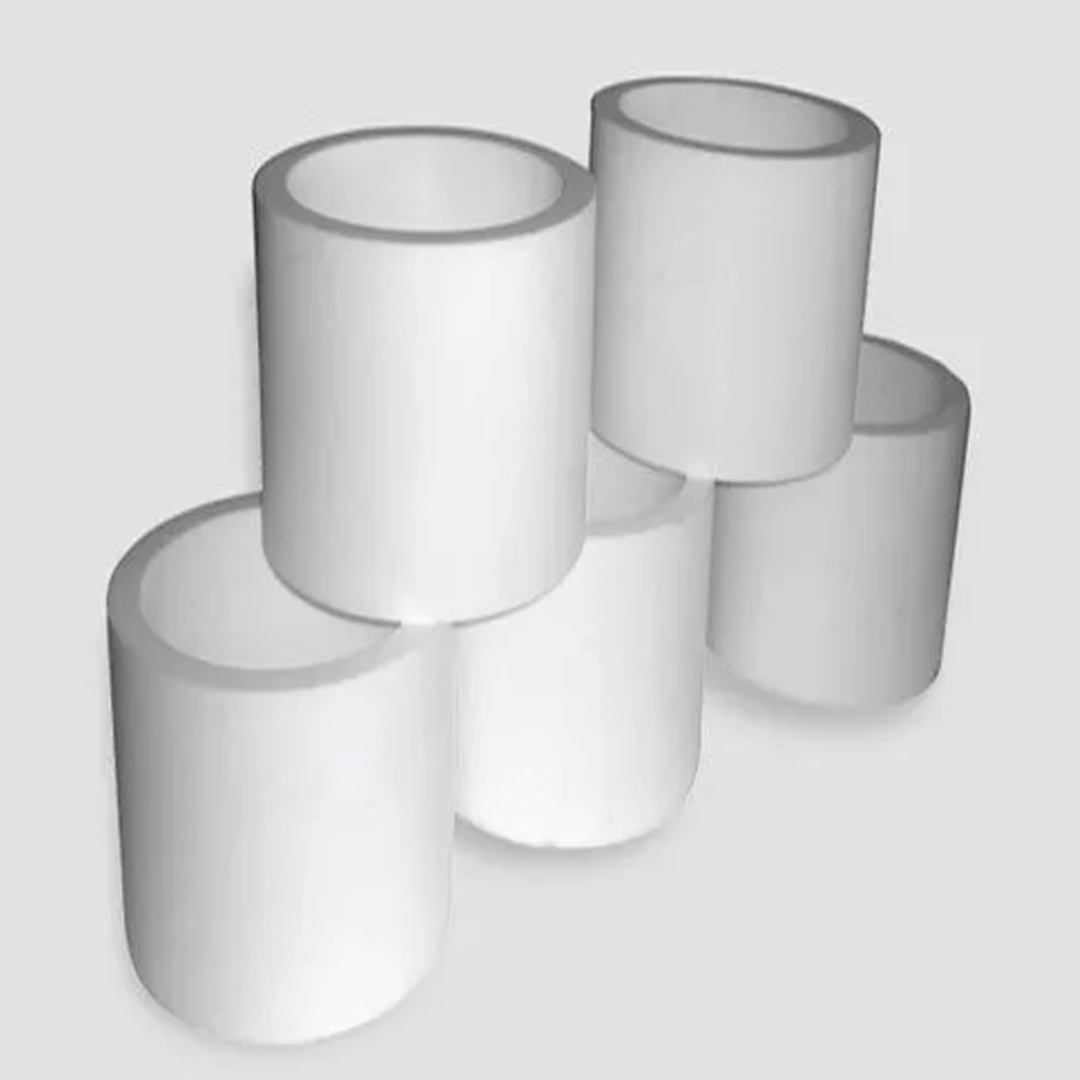

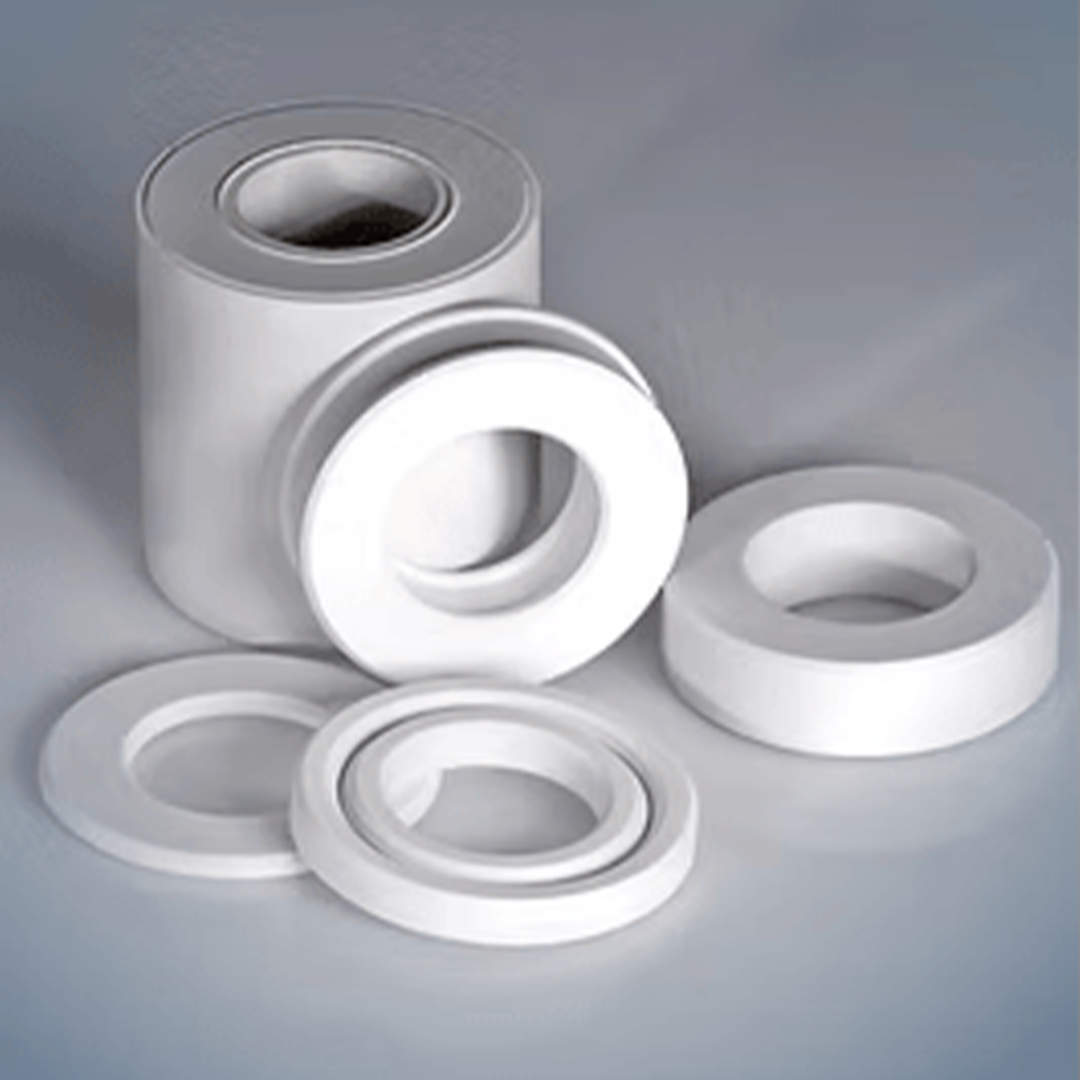

Related Glass-filled PTFE Products

There are many different types of modified PTFE, including glass-filled PTFE. In addition, we have several other related products for specific use.

Glass-Filled Valve Sheet

Valve sheets filled with glass for valve seats and sealing applications. They have good strength, excellent chemical resistance, and long service life. These sheets aid valves to run efficiently under high pressure, heat, and harsh chemical environments.

Glass-Filled Washer

Glass-Filled Washers are glass-filled PTFE to prevent leaks, distribute pressure, and reduce vibration. These are used for mechanical joints, chemical equipment, and pipelines. Their ability to be used in static and dynamic applications makes them strong and chemically resistant.

Glass-Filled Sheet

These sheets are also made of tough glass-filled PTFE design, which can be cut into gaskets, seals, and can also be used as a lining material. Designed to resist both chemicals and heat, they are appropriate for use in tanks, vessels, and processing machines.

Glass-Filled Rods

Solid, strong, and easy to machine, glass-filled rods make up rings or bend bushings, or custom parts. In high-wear mechanical applications where strength, precision, and chemical resistance are critical to long-term performance, they are often used.

Glass-Filled Gasket

Glass-filled PTFE gaskets have very long-lasting seals between two surfaces. Thermal, pressure, and aggressive chemicals resistant, they are perfect for chemical, oil, and industrial environments like chemical pumps, valves, and piping systems.