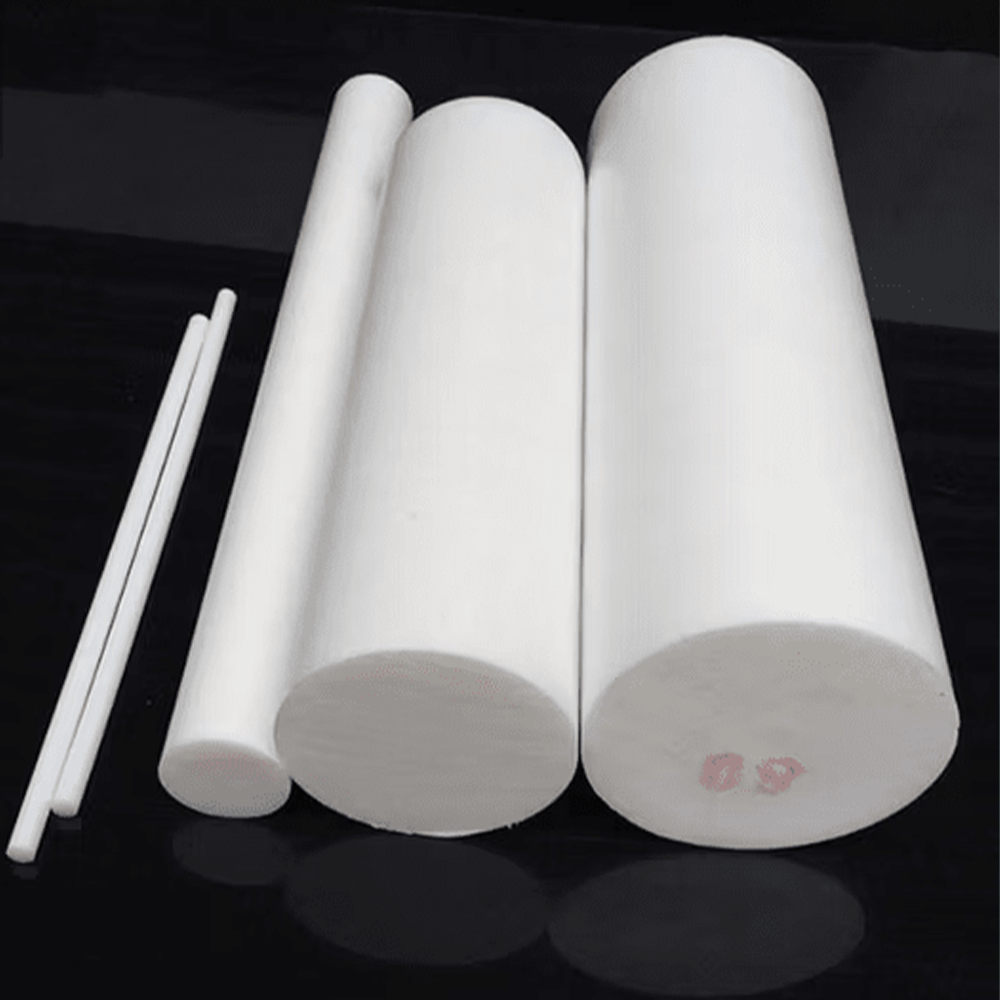

PTFE Rod

PTFE rod or Polytetrafluoroethylene rod is well known for its nonstick and chemical-resistant properties. PTFE rods are made from the same material used in non-stick pans, but in an industrial setting. They are strong and lasting parts that can handle heat, chemicals, and friction.

Durability and Long Lifespan

High-Temperature Resistance

Non-Stick Properties

Electrical Insulation

PTFE rods are used mostly to manufacture machine parts and all kinds of chemical, electrical and mechanical components. This plastic doesn’t react easily with chemicals, doesn’t take water, and can operate in hot or cold conditions. These qualities make PTFE rods in use in various industries where strong, safe, and clean materials are required.

The rods come in different sizes and types. PTFE is made in a soft and flexible or hard and strong way, depending on the type of PTFE made. In addition, they are relatively easy to cut and shape into different pieces.

Remember, PTFE rods are not suitable for all wear applications. It is difficult to bond with everything. Get high-quality virgin PTFE rods for your industry.

PTFE Rods are also useful in many areas as they do not get damaged easily by heat and chemicals. Below are some common applications:

- PTFE rod components are used in parts that deal with acids, alkalis, and other harsh chemicals, in chemical plants

- PTFE does not conduct electricity, which makes it ideal as an insulator for the electrical industry.

- PTFE is safe to use with food & medicine. For this reason, PTFE is used for making clean and nontoxic tools.

- Seals, bearings, bushings, and other parts that need to move smoothly without getting stuck.

- PTFE rods are used in the laboratory in order to stir chemicals safely without any reaction.

Here is a quick look at the common technical details of our PTFE rod:

Property | Value |

Material | 100% Virgin PTFE |

Diameter Range | 10 mm to 200 mm (standard) |

Standard Length | 1000 mm |

Temperature Range | -200°C to +260°C |

pH Range | 0 – 14 |

Thermal Conductivity | 0.25 – 0.69 W/mK |

Max Pressure Capacity | Up to 100 bar (size/design dependent) |

Color | White |

Types Available | Solid Rods, Custom Sizes |

FDA Approved | Yes |

Complies With | ASTM D1710, DIN, EN, ASME Standards |

Key Features | Chemically inert, non-stick, low friction, high electrical insulation, UV resistant, food safe |

Processing Methods | Machining (drilling, turning, milling), water/laser cutting |

Typical Applications | Chemical, food, offshore, electrical, and mechanical industries |

Top Manufacturer & Supplier of Teflon PTFE Rod

Hindustan Polymer is one of the major manufacturers and suppliers of PTFE rods across India. We are famous for our excellent PTFE products that are durable, safe, and reliable. Hindustan Polymer uses advanced technology and high-grade raw materials to produce Teflon rods as per industry standards.

Over the last 20 years of industry expertise, we have established ourselves as a trusted name in the PTFE manufacturing sector. Every month, we produce about 4,00,000 to 5,00,000 PTFE products and deliver them in India.

We crafted our product using 100% virgin PTFE, ensuring exceptional purity and performance. We also have a huge range of rod sizes and even have custom options for specific customers’ needs.

Due to our commitment to quality, we are the best Teflon Rods manufacturer & supplier. Besides PTFE rods, we have a diverse portfolio of PTFE products, including sheets, gaskets, bushings, and custom-moulded components.

Features & Benefits of Hindustan Polymers PTFE Teflon Rods

There are a lot of advantages of Hindustan Polymers PTFE rods that make them suitable for use in industries. Here are the benefits:

- Mechanical Resistance: Even from strong acids or bases, these rods don’t get affected.

- Easy to Clean: Nothing sticks to PTFE easily, so it is easy to clean.

- Wide Temperature Range: Performs excellently in freezing cold and very hot (-200°C to +260°C).

- Insulator: PTFE rod is an electric insulator that doesn’t let electricity pass through, hence safe in electric systems.

- Long and Durable: PTFE rods do not wear out easily and are long-lasting.

Machining & Handling Guidelines

While working with PTFE rods is simple, there are a couple of tricks to make the job easier.

- Use Sharp Tools: PTFE is soft, so sharp tools result in a clean finish without tearing.

- Go Slow: Cut at slow speeds to not heat the material too much.

- Support Long Rods: When shaping/cutting longer rods, support them to not bend.

- Clean Workspace: Make sure the area is clean since PTFE attracts dust and dirt.

- Don’t Pull or Twist: Never pull or twist the rod, as it could get deformed.

Why Choose Hindustan Polymer?

By selecting its PTFE rods supplier, Hindustan Polymer, you get:

- High-Quality Products: All our PTFE rods are made of the best quality raw materials and are strictly checked for quality. This helps the membranes perform in rugged conditions and for longer use in any application.

- Customisation Options: PTFE rods are available in different sizes, lengths, and filled types to meet your specific needs. We deliver with precision on standard size or a custom solution.

- Fast & Reliable Delivery: It is very critical to supply your operations at the right time. For this reason, we guarantee fast and dependable delivery to maintain a smooth workflow.

- Expert Technical Support: You can consult our experienced staff for choosing the right type of PTFE rod according to your usage. For everything from selection to application, we provide guidance.

- Trusted Industry Name: Hindustan Polymer is a well-known brand of respected quality and customer satisfaction. But over the years, we’ve developed the trust of clients from different industries.

FAQs about PTFE Rod

Yes, PTFE rods can be easily machined using standard tools. Their tenderness allows bending, milling and drilling to create custom components. However, due to their low thermal conductivity, care should be taken to manage heat during machining.

Virgin PTFE rods are FDA-approved and are safe for food contact applications. They are non-toxic, chemically passive, and can withstand high temperatures, making them ideal for use in food processing equipment and pots.

PTFE rods can work effectively in temperatures ranging from 200 to +260. This wide range suits them for excessive cold or heat-related applications, such as cryogenics and high-temperature sealing.

PTFE rods have excellent electrical insulation properties. They have a high dielectric power and low wastage factor, which makes them ideal for insulators, spacers and other components in electrical and electronic applications.

Bonding of PTFE sticks to other materials is challenging due to their non-stick surface. However, the treatment of the surface can modify the surface to allow adhesion using the appropriate adhesive.

Related PTFE Rods

Below are some of our most popular and specialised PTFE rods, each designed to offer unique benefits like added strength, improved sliding performance, or better heat resistance. Let’s explore these variants in detail so you can choose the right one for your project.

3mm PTFE Rod

For applications where precision is the main factor, our 3mm PTFE rod is a slim, lightweight rod ideal for compact applications. Used in electronics, lab tools, and small mechanical parts where durability, chemical resistance, and nonstick properties are desired. It is commonly used.

3mm PTFE Rod

Our 3mm PTFE rod has the same strength and performance as other standard PTFE rods, but with a smaller diameter. Small gaskets, seals, and insulators work well in harsh environments or high temperatures and are perfect for manufacturing.

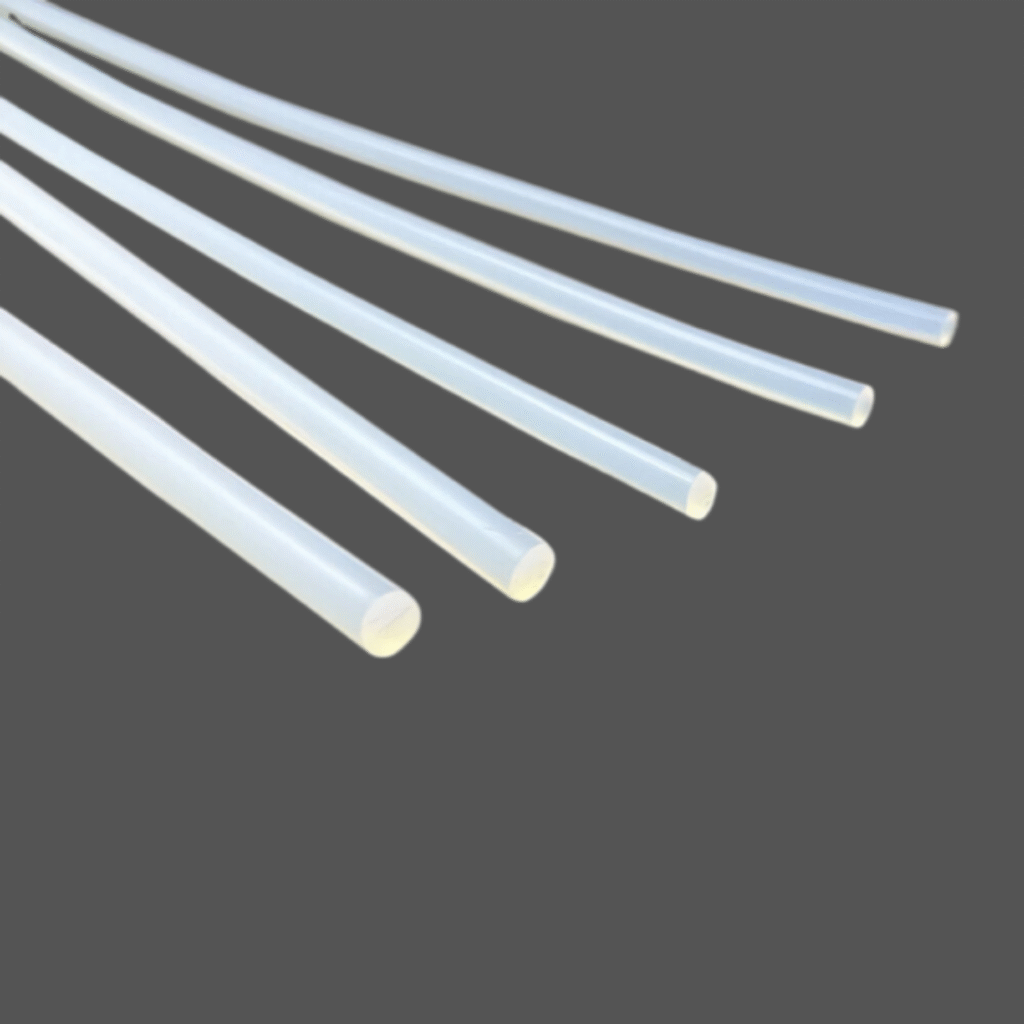

PTFE Stirring Rod

The PTFE stirring rod is supported as not only good for laboratory mixing but also without the fear of contamination or chemical reaction to the stirring rods. The surface is nonstick and easy to clean, and is safe for being handled by the most physically aggressive liquids used in science and research.

PTFE stirring rod

Our PTFE stirring rod is commonly found used in both schools, labs, and industrial testing units. This is made from high-purity PTFE, which means it’s good for stirring acids, bases or readily soluble solutions without affecting their composition.

Carbon-filled PTFE rod

Made for high-strength applications where regular PTFE may wear out, our carbon-filled PTFE rod is filled with our friction-reducing carbon. Carbon added to the cell improves wear resistance as well as stiffness, making it a smart choice for wear items such as bearings, washers, and rings.

Graphite-filled PTFE rod

The graphite-filled PTFE rod offers excellent self-lubricating properties and low friction, reducing wear and extending the life of mechanical parts. For dynamic applications like pressure and motion, it’s great.

Glass Filled PTFE Rod

The glass fibres give some added strength and shape retention to our glass-filled PTFE rod. This type is suited for high load, pressure, and mechanical stress applications (valves, etc.) and is used for compressor parts and support rings.

PTFE Moulded Rod

The PTFE moulded rod is created through the process of moulding to make it more solid and uniform. In industrial machinery and assembly, it offers excellent dimensional tolerance, higher strength, and chemical resistance.

Black PTFE rod

Most commonly, our black PTFE rod is carbon-filled for better wear resistance, along with a nice look. It is a great choice for visible components of machinery or in areas exposed to sunlight, providing very good performance with added UV resistance and mechanical strength.

Extruded PTFE rod

Our extrusion rod is for PTFE rod, which results in a finished and exact diameter. It is widely used in general, such as seals, spacers, and insulating components needing flexibility and consistency.

2mm PTFE rod

The 2mm PTFE rod is among the thinnest available options, which makes it a great choice for very small components in electronics, precision instruments, or lab equipment. Although small, it does the same as regular PTFE in terms of its chemical resistance and nonstick properties.

PTFE Welding Rods

These PTFE welding rods are used to weld PTFE sheets or parts using heat welding. In fabrication work, when PTFE structures or containers are made of large PTFE members, they are used to make a strong, leakproof bond with heat and chemical resistance.